How Heat Exchangers Work in Dairy Pasteurization

Sign Up for Maintenance Tips

Posted on Jul 20, 2022 10:32:19 AM by AGC Heat Transfer | 8 min. read

Table of Contents

What's the Difference Between Pasteurization and Sterilization?

Pasteurized vs. Unpasteurized Milk

Unique Needs of Dairy Heat Exchangers

From milk and yogurt to cheese and ice cream, pasteurization is an essential step to producing safe, consumable dairy products.

So, how is milk pasteurized? How does pasteurization work? And how do heat exchangers work to make pasteurization happen? Let’s start at the beginning.

What Is Pasteurization?

Simply put, dairy pasteurization is used to reduce potentially harmful pathogens to help keep dairy products safe for consumption and extend shelf life. Today, pasteurization is a standardized process.

Unpasteurized dairy can contain harmful bacteria that can lead to serious illness. The pasteurization process heats dairy products for a determined time to a specific temperature that reduces the presence of harmful bacteria.

What’s the Difference Between Pasteurization and Sterilization?

Both pasteurization and sterilization are thermal processes used to create safe, consumable products.

Sterilization is a process used to eliminate all bacteria and pathogens from a product, whereas pasteurization allows certain bacteria to remain. During sterilization, all microorganisms are either removed or killed out of a product, making it an ideal use for products that will not be refrigerated or that require a long shelf life; however, the product will lose some of its vitamins and sensory characteristics in the process.

Through pasteurization, a level of healthy bacteria remains in the product while preserving the nutritional value and sensory qualities of the unprocessed product. While these products do not have as long of a shelf life (usually only several weeks), they maintain the majority of the original product’s characteristics.

Pasteurized vs. Unpasteurized Milk

Since the 1980s, the FDA has allowed only pasteurized milk to be sold across state lines.

Raw milk is milk that isn’t heated to kill the microorganisms present in the natural dairy product. Because raw milk has not been subject to a heating process, it still contains all of its original bacteria and pathogens, meaning that it has additional nutrients and vitamins that pasteurized milk does not; however, raw milk introduces higher risks of foodborne outbreaks.

Pasteurized milk is heated to kill off some (but not all) of the microorganisms found in raw milk. This process makes the milk safe to drink and extends its shelf life without denaturing the milk’s vitamins and nutrients.

How Do You Pasteurize Milk?

Heating your product is an important — and possibly the most important — step in the dairy production process. Bringing a product up to the right temperature to kill bad bacteria (as indicated by the Pasteurized Milk Ordinance) ultimately sets you up for success downstream. In fact, if a product does not achieve the right temperature for the right duration of time, an entire day's worth of product can go to waste.

A dairy plant may choose to run their product through a heat exchanger at a higher temperature over a shorter time, or they may choose to run their product at a lower temperature for a longer period of time. Some plants may even choose to pasteurize their product in a vat. No matter the method, temperature and time work in tandem to properly pasteurize a plant’s product — and there are several ways to do it.

What Is High-Temperature, Short-Time Pasteurization?

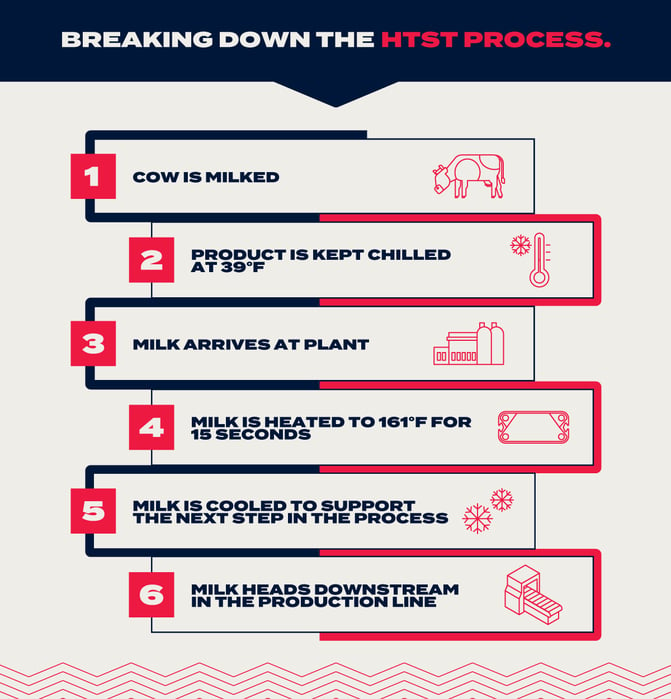

High-temperature, short-time (HTST) pasteurization is exactly what it sounds like — using a heat exchanger, the product continuously flows through heat exchanger plates, raising the product’s temperature to at least 161 degrees Fahrenheit. The product is heated to the desired temperature and held there for a designated amount of time, after which it is rapidly cooled.

An HTST process helps make a product safe to consume without changing the product’s nutritional value or sensory characteristics. Milk that is used for further processing typically goes through the HTST process.

What Is Ultra-High Temperature Pasteurization?

Ultra-high temperature (UHT) pasteurization, otherwise known as ultrapasteurization or ultra-heat treatment, is when a plant heats milk or cream to a high temperature for a short period of time to kill bacteria. This process often kills more bacteria than traditional pasteurization, which helps dairy companies prolong shelf life (or even create shelf-stable products). Most milk that is sold in stores today undergoes UHT during its production.

Some dairy products that undergo UHT can be stored without refrigeration in sterile five-layer laminated boxes or metal cans. These UHT products have a shelf life of six months to one year.

Specific Heat Temperatures for Dairy Products

To properly pasteurize your dairy product, dairy plants must closely follow FDA standards:

|

Temperature |

Time duration |

Pasteurization type |

|

145°F |

30 minutes |

Batch pasteurization, also called low-temperature pasteurization |

|

161°F |

15 seconds |

High-temperature short-time (HTST) pasteurization |

|

280°F |

4 – 5 seconds |

Ultra-high temperature (UHT) pasteurization |

Dairy Plate Coolers

Because pasteurized milk is not sterile, the product must be immediately cooled to below 39 degrees Fahrenheit after heating to protect it from microbial growth and further protein denaturation. Oftentimes, this chilling is achieved using regenerative heat exchange, through which the incoming cold milk cools the outgoing hot milk, saving energy.

When this heating and cooling process is followed correctly, milk products should have a safe shelf life of around 14 days (if properly refrigerated).

Unique Needs of Dairy Heat Exchangers

Dairy and milk products require regular heat exchanger CIP. Dairy plants that invest in hydraulic frame heat exchangers are able to better optimize their process and decrease downtime. These frames allow dairy plants to open their heat exchanger with the press of a button, reducing the time and effort required for maintenance.

What Is a Heat Exchanger PlateCheck?

The plates in your dairy plant’s heat exchanger are critical to bringing your product to the right temperature — so making sure that there are no leaks or cross-contamination is critical to your production process. That’s why we recommend regular plate checks.

AGC offers the only plate checks that specifically meet 3A-Standards, and the dye we use to check for leaks is 100% food safe. These checks also help us check the condition of your heat exchanger’s frame, gaskets, and CIP response to identify any immediate issues, or costs you might face in the near future. This preventative maintenance can help your catch issues before they cause major headaches during both your audit and your production process.

Best of all, we can test any model unit of any size. And if you need new plates, AGC’s ProFlow plates fit into select competitor’s heat exchangers and are more than capable of taking on a wide range of setpoints or viscosity, including that needed for cheese, yogurt, ice cream, whey, and permeate.

Building Custom Heat Exchangers for Dairy Plants

AGC works with many dairy plants to help them optimize their pasteurization process.

For example, we have an ongoing relationship with several large Greek yogurt plants across the nation. These plants require unique processes that are optimized for both their unique products and the large size of their plants.

We work side by side to create specific equipment that is designed to optimize efficiency and keep up with high volume demands. And when these plants change their product or run into production issues, we are there to help make adjustments and repairs to keep production volumes steady and downtime to a minimum.

What You Get With an AGC Heat Exchanger

AGC’s heat exchangers are designed to make sure that heat transfer is consistent and as efficient as possible. We design our equipment to not only meet the designated temperature of your product, but to meet your expectations and reduce downtime.

For example, if you need your heat exchanger to run 20 hours, and want to set aside 4 hours for cleaning, we can design your equipment to make that a reality. Whatever you want to produce, or however you want to optimize your production line, we can take care of the details to make it possible.

We go beyond designing and building heat exchangers to make sure that your equipment is working at an optimal level. Whether you’re changing products, or expanding and in need of a brand new heat exchanger, we can help.

Ready to optimize your pasteurization process? We can inspect your heat exchanger, replace parts, or help you weigh the pros and cons of a new heat exchanger for your plant. Talk to an AGC team member today.