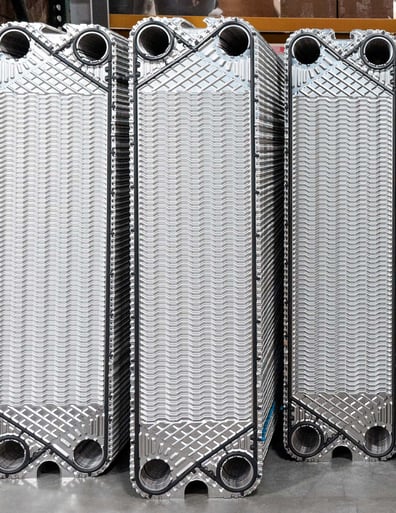

6 Advantages a Sanitary Plate Heat Exchanger Brings to Prepared Food Production

Sign Up for Maintenance Tips

Posted on Mar 5, 2024 12:31:28 PM by AGC Heat Transfer | 3 min. read

In the high-pressure arena of prepared foods, keeping your operation efficient, reliable, and quality-focused isn’t just a goal — it’s a necessity.

Whether you're depending on a trusty shell-and-tube heat exchanger or an older plate heat exchanger (PHE), there's a good chance an upgrade is in your future. So, if replacing your heat exchanger has even crossed your mind in the past, here are six reasons you might get the most benefit from a new, custom-built plate heat exchanger.

Get More Efficient, Dependable Production

Right now, your heat exchangers might take up a huge footprint, have constant leak issues, or it might even be a nightmare to maintain. The right PHE in your plant will drastically minimize these basic challenges while also giving you:

Longer uninterrupted runs: Cut back on unexpected downtime from cleaning, leaks, or overheating issues, leading to happier employees, fewer headaches, and higher production volumes.

Longer uninterrupted runs: Cut back on unexpected downtime from cleaning, leaks, or overheating issues, leading to happier employees, fewer headaches, and higher production volumes.- Reduced cross-contamination risk: When you invest in a high-quality PHE and plates, you can rest easy knowing that your gaskets and seals will keep leaks at bay. That also offers a consistently clean and safe production environment. No more cross-contamination worries.

- A safer working environment: When you upgrade your unit to one that is structurally sound — and hasn't ensured years of runtime and abuse — you create a safer (and more efficient) workplace. Upgraded equipment can also operate at lower temperatures and include leak-resistant gaskets. This not only minimizes risk for your floor staff but provides the longest life possible for your plates and gaskets.

- Easier preventative maintenance: Access to all heat transfer surfaces (i.e., your plates) makes inspection, cleaning, and sanitation much less labor-intensive. A PHE is designed to open for full access to your plate pack — and with a hydraulic frame, you can open your equipment in a matter of minutes.

- Energy efficiency: No doubt, your plant's energy bills consume a decent chunk of your regular plant costs. PHEs can operate on a closed-loop system, requiring less cooling water and saving you valuable resources and money. They can also utilize regenerative energy to repurpose valuable BTUs in your process.

- Scalability to match consumer demand: Scale up or down by easily adding or removing plates. Need to ramp up production to meet seasonal demands? PHEs can adapt seamlessly and give you ultimate control over production volume.

Bonus Benefit: Replaceable Ports by AGC

Does your operation include running high acid or corrosive product? Have you had to replace entire heat exchangers due to corroded ports?

Does your operation include running high acid or corrosive product? Have you had to replace entire heat exchangers due to corroded ports?

AGC's new plate heat exchanger's design allow easy replacement of common wear components (like ports) to extend your equipment's lifespan without sizable investments. And AGC's unique use of a corrosion-resistant high nickel alloy means that while your inlet or outlet can be replaced, you won't need to replace them frequently.

Thinking About Your Next Heat Exchanger?

AGC's custom-built PHE frames offer unmatched efficiency, reliability, and quality. Not only do we work with nearly any brand or model PHE in the industry, but we design and build top-tier frames that meet the needs of the plants we work with every day.

Ready to see what a top-of-the-line PHE can do for you?

P.S. Share this post with your fellow production leaders! Your operator colleagues will thank you.