Plate Heat Exchanger Resources

All of our resources, conveniently in one place.

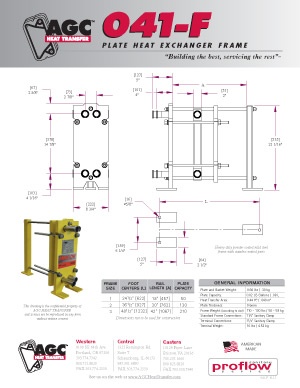

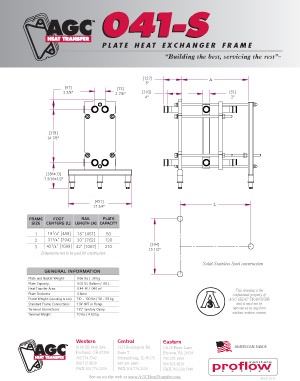

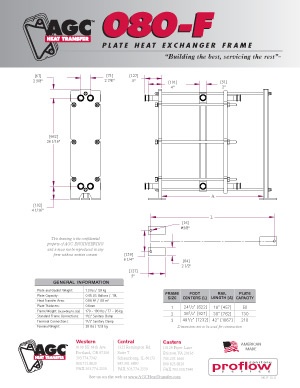

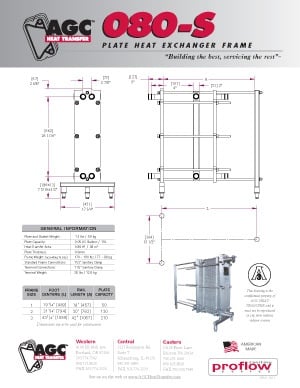

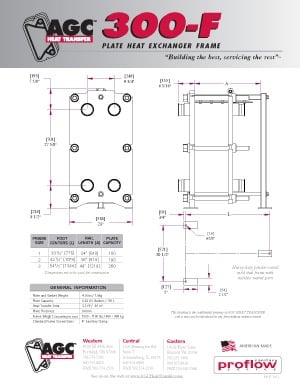

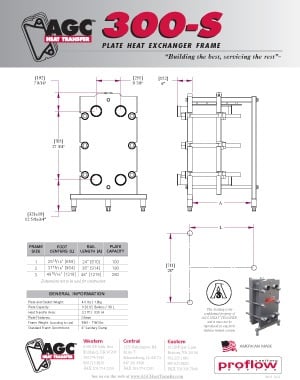

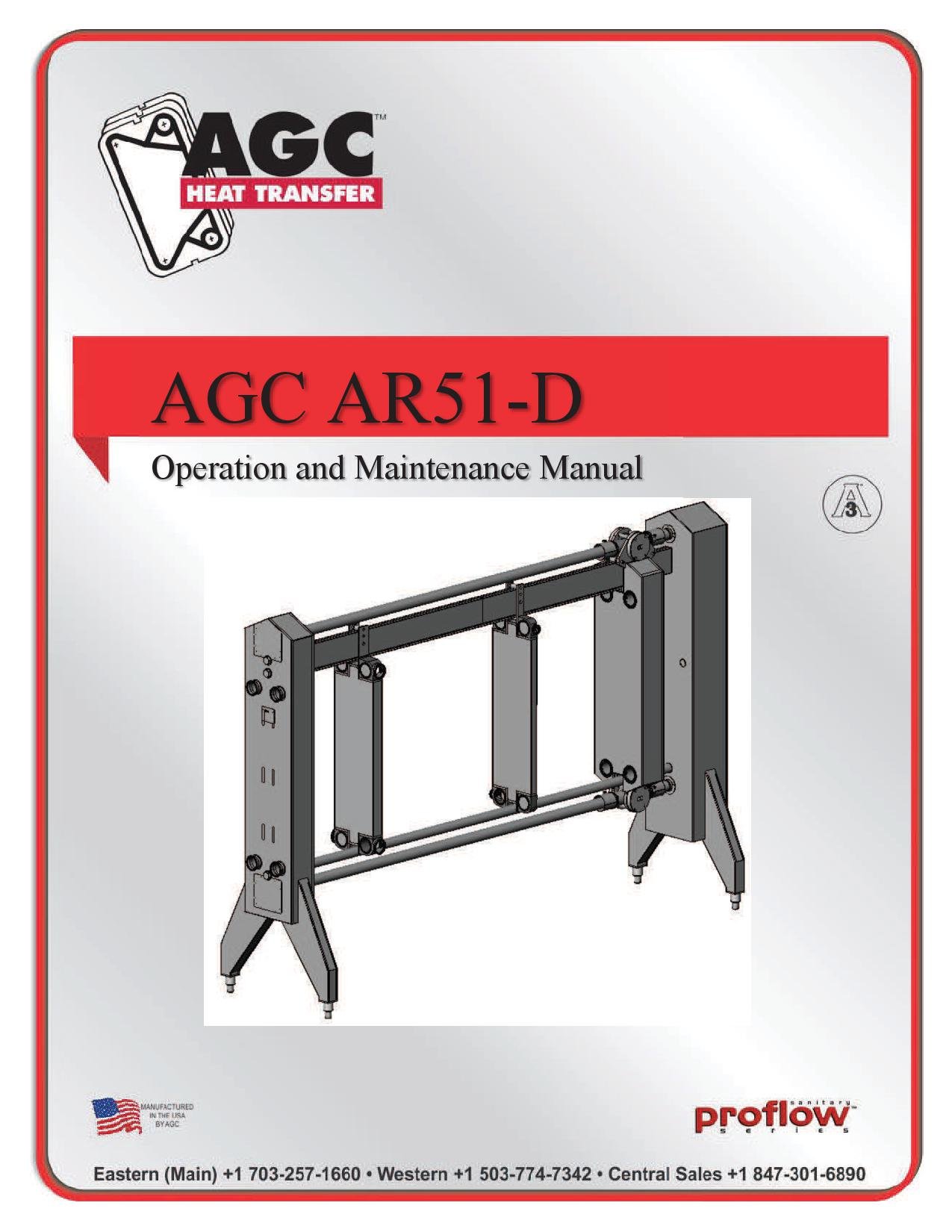

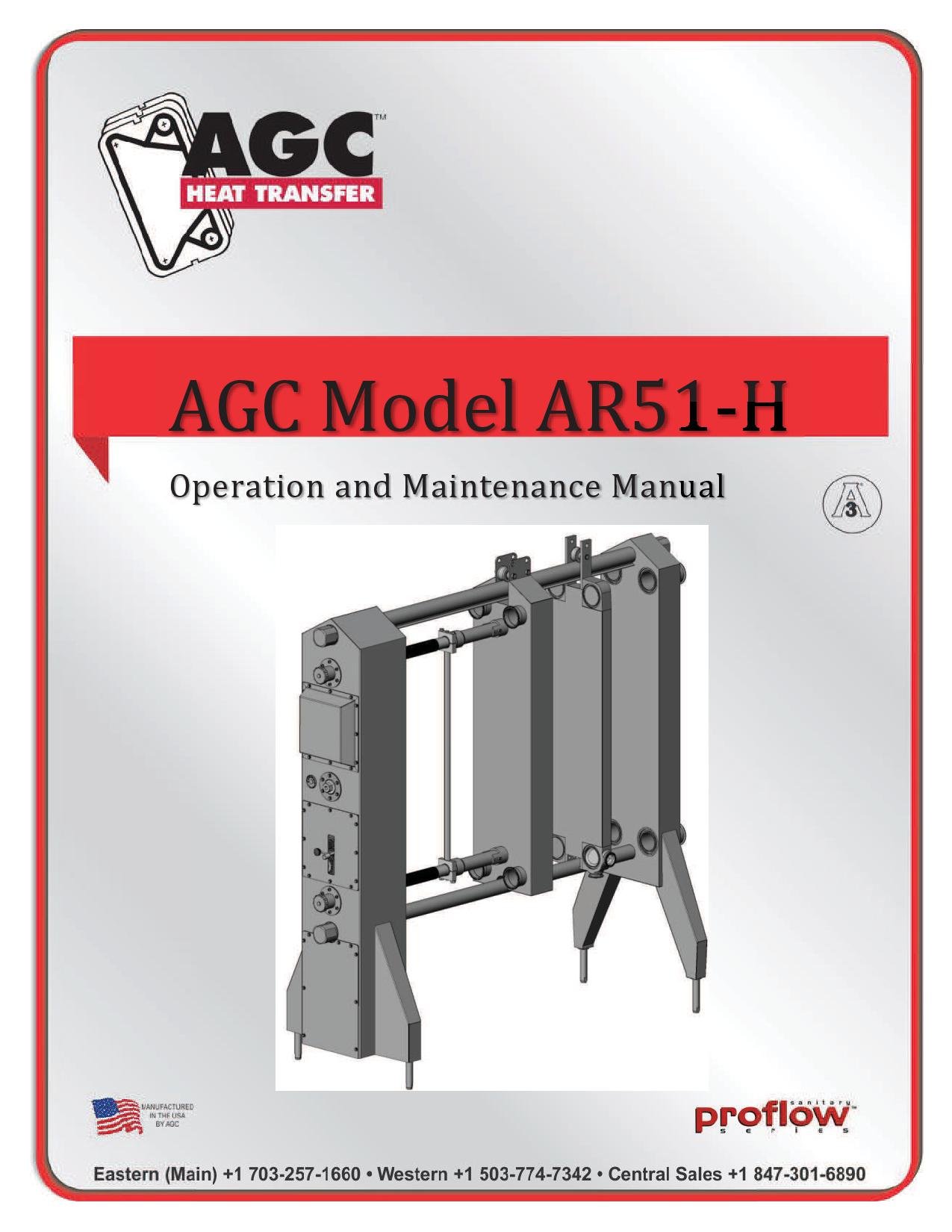

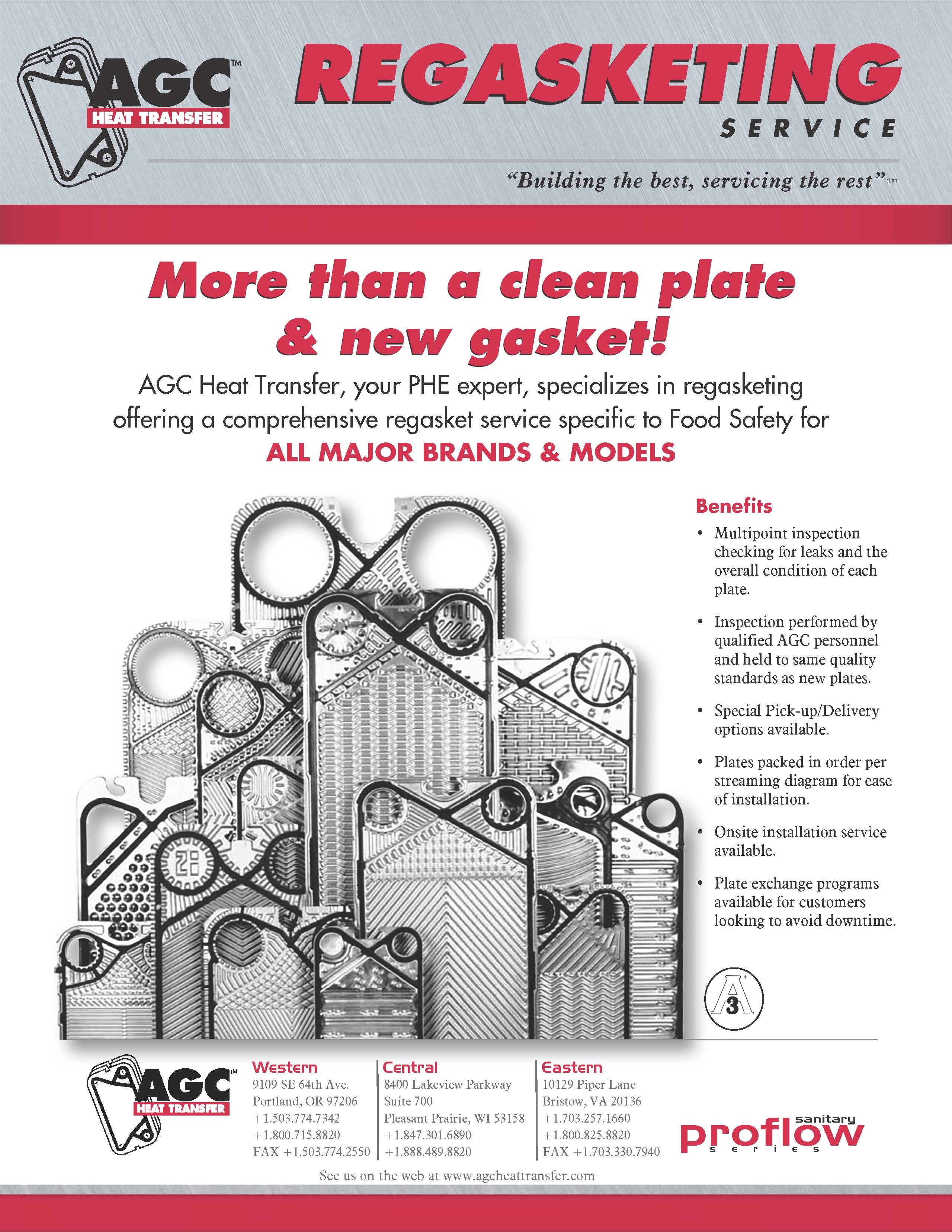

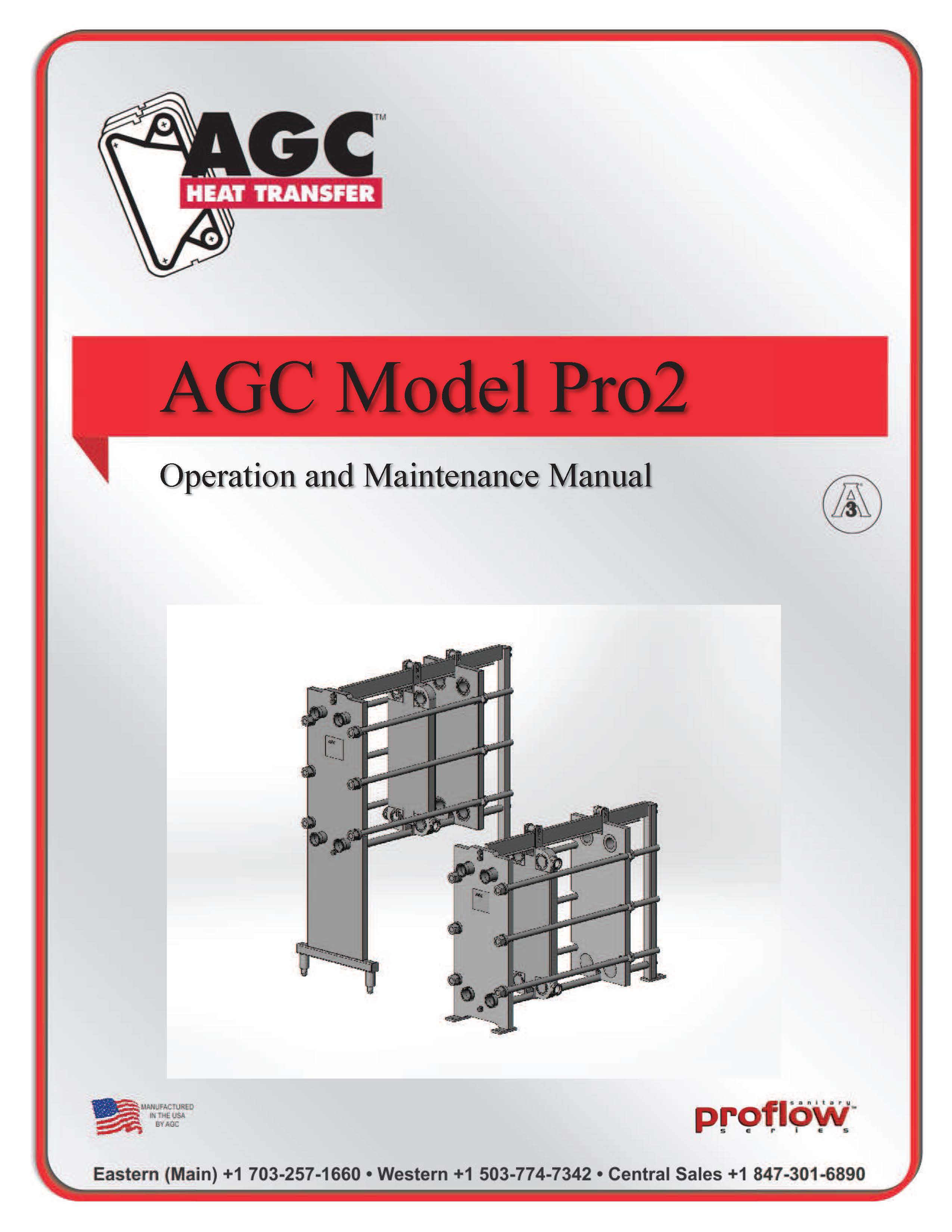

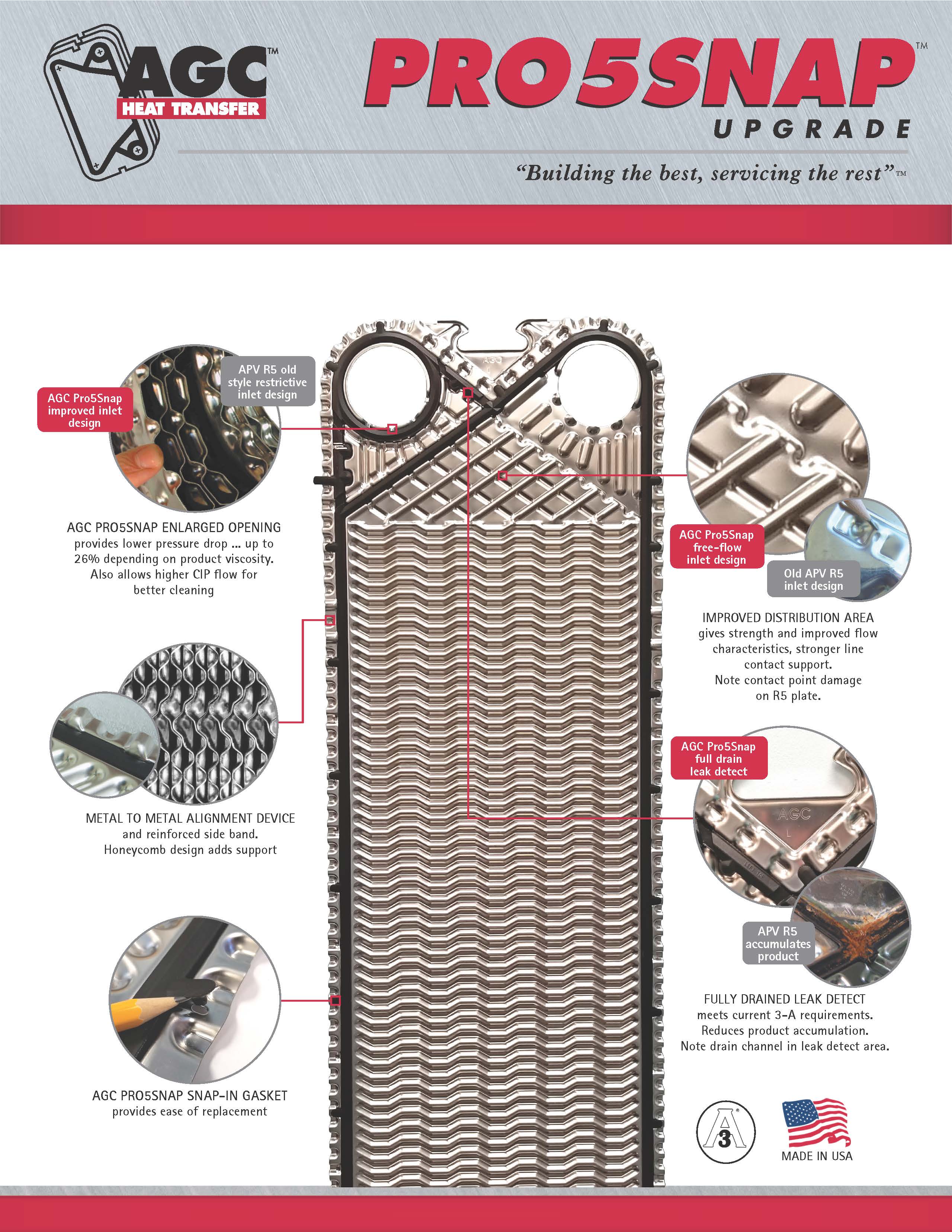

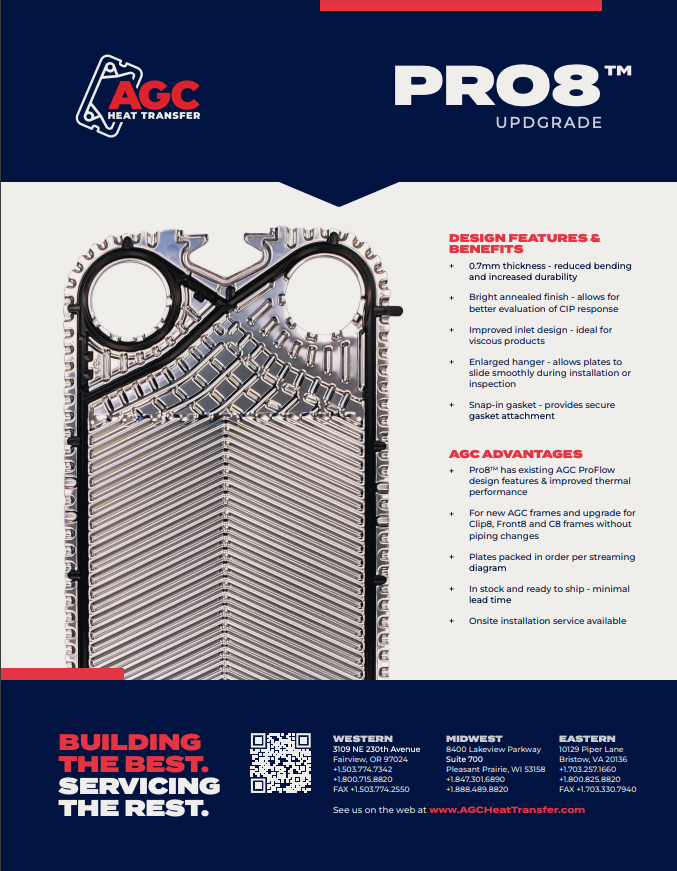

For ease and accessibility, we’ve gathered all our resources and put them in one place. Here you will find product specification sheets for all AGC frame models, literature detailing the features of our food-specific designed ProFlow series plates, and operation manuals for all AGC plate heat exchangers.

.jpg)